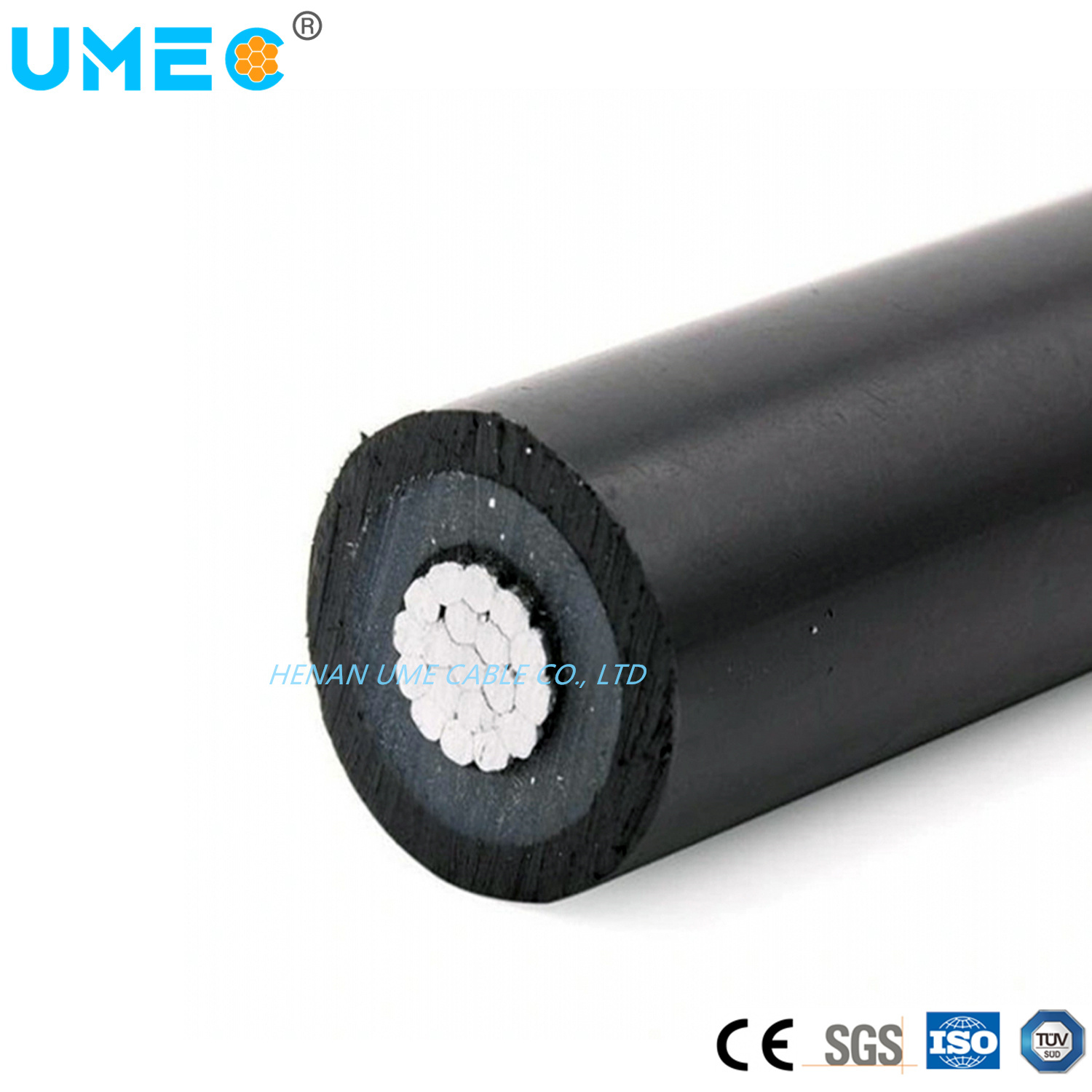

N2xrh Fe 180 Fire Resistant Armoured Power Cable Cu/Mgt/XLPE/Lsfoh/Swa/Lsfoh

N2xrh Fe 180 Fire Resistant Armoured Power Cable Cu/Mgt/XLPE/Lsfoh/Swa/Lsfoh image

Get Latest Price Request a quote

You May Like

Product Details

Product Description

N2xrh Fe 180 Fire Resistant Armoured Power Cable Cu/Mgt/XLPE/Lsfoh/Swa/Lsfoh

As an energy cable, it is used in places where fire and toxic smoke may pose a danger to people, such as industry, switchgear, underground facilities and city networks, hotels, tunnels, schools, hospitals, shopping and business centers. It is suitable for underground and external use.

1. Overview

N2XRY cables and N2XRH cables form part of our range of steel wire armoured low voltage power cables we offer in our portfolio. These cables are the copper conductor equivalent of the NA2XRH and NA2XRY cables, delivering a voltage rating of 0.6/1kV (600V/1000V) and a maximum temperature rating of 90oC. The addition of SWA armouring allows for these cables to be direct buried in the ground without additional protection, protecting them from mechanical stresses and the risk of damage from external forces. The black outer sheath offers UV protection in keeping with their use outdoors.

N2XRY is a PVC insulated and sheathed cable, comparable to the British standard cable BS5467. The N2XRH cable uses Low Smoke Zero Halogen compounds (also known as HFFR – halogen free flame retardant) and is comparable to the BS6724cable. The LSZH cable provides additional protection in the event of a fire, emitting none of the harmful halogen gases such as chlorine gas and emits reduced levels of the dense black smoke compare to PVC sheathed cables. As a result, the N2XRH cable is widely used in public buildings, tall constructions, as well as in refineries, automation plants and data centres – application where smoke emissions and toxic fumes could pose a risk to human health and sensitive equipment in the event of a fire.

2. Cable Types

N2XRH / N2XRY CABLE CODE

| N | Standard metal cable type (copper) |

| 2X | XLPE insulation |

| R | Round steel wire armour |

| H | HFFR outersheath |

| Y | PVC outersheath |

3. Construction Table

| N2XRY CABLE | N2XRH CABLE | ||

|---|---|---|---|

| N2XRY CABLE | N2XRH CABLE | N2xrh Fe 180 | |

| VOLTAGE |

0.6/1kV |

0.6/1 kV | 0.6/1kV |

| CONDUCTOR |

Class 2 Stranded Copper |

Class 2 Stranded Copper | Class 2 Stranded Copper |

| Fire resistance | MICA | ||

| INSULATION |

XLPE (Cross-Linked Polyethylene) |

||

| BEDDING |

PVC (Polyvinyl Chloride) |

LSZH (Low Smoke Zero Halogen) |

LSZH (Low Smoke Zero Halogen) |

| ARMOUR |

SWA (Galvanised Steel Wire) |

SWA (Galvanised Steel Wire) | |

| OUTER SHEATH |

PVC (Polyvinyl Chloride) |

LSZH (Low Smoke Zero Halogen) |

LSZH (Low Smoke Zero Halogen) |

4. Dimensions

| Nominal Section |

Outside Diameter (Approx.) |

Net Weight (Approx.) |

Shipping Length |

DC Resistance of Conductor at 20°C max. |

Current Carrying Capacity |

|

| (mm²) | (mm) | (kg/km) | (m) | (ohm/km) | In soil at 20°C | At 30°C in the air |

| 1×4 | 11.4 | 218 | 1000 | 4.61 | 55 | 47 |

| 1×6 | 11.8 | 248 | 1000 | 3.08 | 68 | 59 |

| 1×10 | 13.1 | 310 | 1000 | 1.83 | 91 | 81 |

| 1×16 | 14.2 | 387 | 1000 | 1.15 | 117 | 109 |

| 1×25 | 16.7 | 551 | 1000 | 0.727 | 150 | 146 |

| 1×35 | 17.8 | 661 | 1000 | 0.524 | 179 | 179 |

| 1×50 | 19.5 | 820 | 1000 | 0.387 | 211 | 218 |

| 1×70 | 22.0 | 1084 | 1000 | 0.268 | 257 | 275 |

| 1×95 | 23.9 | 1361 | 1000 | 0.193 | 304 | 336 |

| 1×120 | 25.6 | 1616 | 1000 | 0.153 | 341 | 388 |

| 1×150 | 27.7 | 1956 | 1000 | 0.124 | 377 | 438 |

| 1×185 | 30.0 | 2364 | 1000 | 0.0991 | 418 | 501 |

| 1×240 | 33.8 | 3036 | 500 | 0.0754 | 469 | 508 |

| 1×300 | 36.9 | 3790 | 500 | 0.0601 | 514 | 654 |

| 1×400 | 40.9 | 4708 | 500 | 0.0470 | 565 | 733 |

| 2×1.5 | 13.8 | 358 | 1000 | 12.1 | 31 | 25 |

| 2×2.5 | 14.6 | 405 | 1000 | 7.41 | 40 | 33 |

| 2×4 | 16.4 | 563 | 1000 | 4.61 | 52 | 43 |

| 2×6 | 17.4 | 648 | 1000 | 3.08 | 65 | 54 |

| 2×10 | 19.9 | 828 | 1000 | 1.83 | 87 | 75 |

| 2×16 | 22.8 | 1160 | 1000 | 1.15 | 113 | 100 |

| 2×25 | 26.0 | 1528 | 1000 | 0.73 | 146 | 136 |

| 2×35 | 28.4 | 1867 | 1000 | 0.524 | 176 | 165 |

| 2×50 | 31.9 | 2365 | 1000 | 0.387 | 208 | 201 |

| 2×70 | 36.6 | 3187 | 500 | 0.268 | 256 | 255 |

| 2×95 | 41.1 | 4088 | 500 | 0.193 | 307 | 314 |

| 2×120 | 45.9 | 5117 | 500 | 0.153 | 349 | 364 |

| 2×150 | 50.7 | 6316 | 500 | 0.124 | 391 | 416 |

| 2×185 | 55.2 | 7461 | 250 | 0.0991 | 442 | 480 |

| 2×240 | 61.5 | 9126 | 250 | 0.0754 | 509 | 565 |

| 2×300 | 66.9 | 10940 | 250 | 0.0601 | – | – |

| 2×400 | 76.2 | 14483 | 250 | 0.0470 | – | – |

| 3×1.5 | 14.3 | 391 | 1000 | 12.1 | 31 | 24 |

| 3×2.5 | 15.2 | 448 | 1000 | 7.41 | 40 | 32 |

| 3×4 | 17.1 | 614 | 1000 | 4.61 | 52 | 42 |

| 3×4 rm | 17.6 | 655 | 1000 | 4.61 | 52 | 42 |

| 3×6 | 18.1 | 736 | 1000 | 3.08 | 64 | 53 |

| 3×10 | 20.9 | 954 | 1000 | 1.83 | 86 | 74 |

| 3×16 | 23.9 | 1354 | 1000 | 1.15 | 112 | 98 |

| 3×25 | 27.4 | 1839 | 1000 | 0.727 | 145 | 133 |

| 3×35 | 30.1 | 2232 | 1000 | 0.524 | 174 | 162 |

| 3×50 | 34.7 | 3050 | 1000 | 0.387 | 206 | 197 |

| 3×70 | 39.3 | 3963 | 1000 | 0.268 | 254 | 250 |

| 3×95 | 43.7 | 5011 | 500 | 0.193 | 305 | 308 |

| 3×120 | 48.8 | 6362 | 500 | 0.153 | 348 | 359 |

| 3×150 | 53.9 | 7750 | 500 | 0.124 | 392 | 412 |

| 3×185 | 58.8 | 9264 | 250 | 0.0991 | 444 | 475 |

| 3×240 | 65.5 | 11331 | 250 | 0.0754 | 517 | 564 |

| 3×300 | 71.4 | 13741 | 250 | 0.0601 | 585 | 649 |

| 3×400 | 81.8 | 18015 | 250 | 0.0470 | 671 | 761 |

| 3×16+10 | 25.1 | 1571 | 1000 | 1.15 – 1.83 | 112 | 98 |

| 3×25+16 | 28.8 | 2131 | 1000 | 0.727 – 1.15 | 145 | 133 |

| 3×35+16 | 31 | 2517 | 1000 | 0.524 – 1.15 | 174 | 162 |

| 3×50+25 | 36 | 3492 | 1000 | 0.387 – 0.727 | 206 | 197 |

| 3×70+35 | 40.7 | 4399 | 500 | 0.268 – 0.524 | 254 | 250 |

| 3×95+50 | 46.5 | 6031 | 500 | 0.193 – 0.387 | 305 | 308 |

| 3×120+70 | 51.5 | 7317 | 500 | 0.153 – 0.268 | 348 | 359 |

| 3×150+70 | 55.5 | 8601 | 250 | 0.124 – 0.268 | 392 | 412 |

| 3×185+95 | 61.3 | 10296 | 250 | 0.0991 – 0.193 | 444 | 475 |

| 3×240+120 | 67.7 | 12530 | 250 | 0.0754 – 0.153 | 517 | 564 |

| 3×300+150 | 75.3 | 16338 | 250 | 0.0601 – 0.124 | 585 | 649 |

| 3×400+185 | 84.3 | 19782 | 250 | 0.0470 – 0.0991 | 671 | 761 |

| 4×1.5 | 16.1 | 517 | 1000 | 12.1 | 31 | 24 |

| 4×2.5 | 17.0 | 599 | 1000 | 7.41 | 40 | 32 |

| 4×4 | 18.2 | 736 | 1000 | 4.61 | 52 | 42 |

| 4×6 | 19.3 | 861 | 1000 | 3.08 | 64 | 53 |

| 4×10 | 23.1 | 1282 | 1000 | 1.83 | 86 | 74 |

| 4×16 | 25.7 | 1673 | 1000 | 1.15 | 112 | 98 |

| 4×25 | 29.8 | 2283 | 1000 | 0.727 | 145 | 133 |

| 4×35 | 33.6 | 3022 | 1000 | 0.524 | 174 | 162 |

| 4×50 | 38.3 | 3958 | 1000 | 0.387 | 206 | 197 |

| 4×70 | 42.9 | 5112 | 500 | 0.268 | 254 | 250 |

| 4×95 | 48.9 | 6936 | 500 | 0.193 | 305 | 308 |

| 4×120 | 53.9 | 8383 | 500 | 0.153 | 348 | 359 |

| 4×150 | 59.2 | 10069 | 250 | 0.124 | 392 | 412 |

| 4×185 | 65.1 | 12108 | 250 | 0.0991 | 444 | 475 |

| 4×240 | 73.5 | 15971 | 250 | 0.0754 | 517 | 564 |

| 4×300 | 80.5 | 19243 | 250 | 0.0601 | 585 | 649 |

| 4×400 | 90.1 | 23359 | 250 | 0.0470 | 671 | 761 |

| 5×1.5 | 17.0 | 592 | 1000 | 12.1 | 31 | 24 |

| 5×2.5 | 18.1 | 693 | 1000 | 7.41 | 40 | 32 |

| 5×4 | 19.3 | 838 | 1000 | 4.61 | 52 | 42 |

| 5×6 | 20.6 | 994 | 1000 | 3.08 | 64 | 53 |

| 5×10 | 24.8 | 1531 | 1000 | 1.83 | 86 | 74 |

| 5×16 | 27.7 | 2000 | 1000 | 1.15 | 112 | 98 |

| 5×25 | 33.3 | 2926 | 1000 | 0.727 | 145 | 133 |

| 5×35 | 36.6 | 3685 | 1000 | 0.524 | 174 | 162 |

| 5×50 | 41.7 | 4787 | 500 | 0.387 | 206 | 197 |

| 5×70 | 47.9 | 6540 | 500 | 0.268 | 254 | 250 |

| 5×95 | 53.9 | 8531 | 500 | 0.193 | 305 | 308 |

| 5×120 | 58.9 | 10223 | 250 | 0.153 | 348 | 359 |

| 5×150 | 65.3 | 12236 | 250 | 0.124 | 392 | 412 |

| 5×185 | 71.4 | 14709 | 250 | 0.0991 | 444 | 475 |

| 5×240 | 81.1 | 19439 | 250 | 0.0754 | 517 | 564 |

| 5×300 | 88.3 | 23520 | 250 | 0.0601 | 585 | 649 |

| 5×400 | 99.1 | 28648 | 250 | 0.0470 | 671 | 761 |

| 7×1.5 | 18.2 | 677 | 1000 | 12.1 | 19 | 16 |

| 7×2.5 | 19.3 | 792 | 1000 | 7.41 | 24 | 21 |

| 12×2.5 | 23.5 | 1228 | 1000 | 7.41 | 19 | 17 |

| 12×2.5 rm | 24.5 | 1279 | 1000 | 7.41 | 19 | 17 |

| 19×2.5 | 27.3 | 1627 | 1000 | 7.41 | 16 | 14 |

| 19×2.5 rm | 28.7 | 1736 | 1000 | 7.41 | 16 | 14 |

1. Where a conductor operates at a temperature exceeding 70ºC it must be ascertained that the equipment connected to the conductor is suitable for the conductor operating temperature.

2. Where cables in this table are connected to equipment or accessories designed to operate at a temperature not exceeding 70ºC , the current ratings given in the equivalent table for 70ºC thermoplastic insulated cables must be used.

For more information, don’t hesitate to call us on Vivian Yuan or send inquiry to me.

We are China N2xrh Fe 180 Fire Resistant Armoured Power Cable Cu/Mgt/XLPE/Lsfoh/Swa/Lsfoh manufacture and supplier,You can get more details with Email,you will get cheap price or factory price.

Get Latest Price Request a quote

Tags: Henan Hongda Cable Co., Ltd., N2xrh Cable, Power Cable