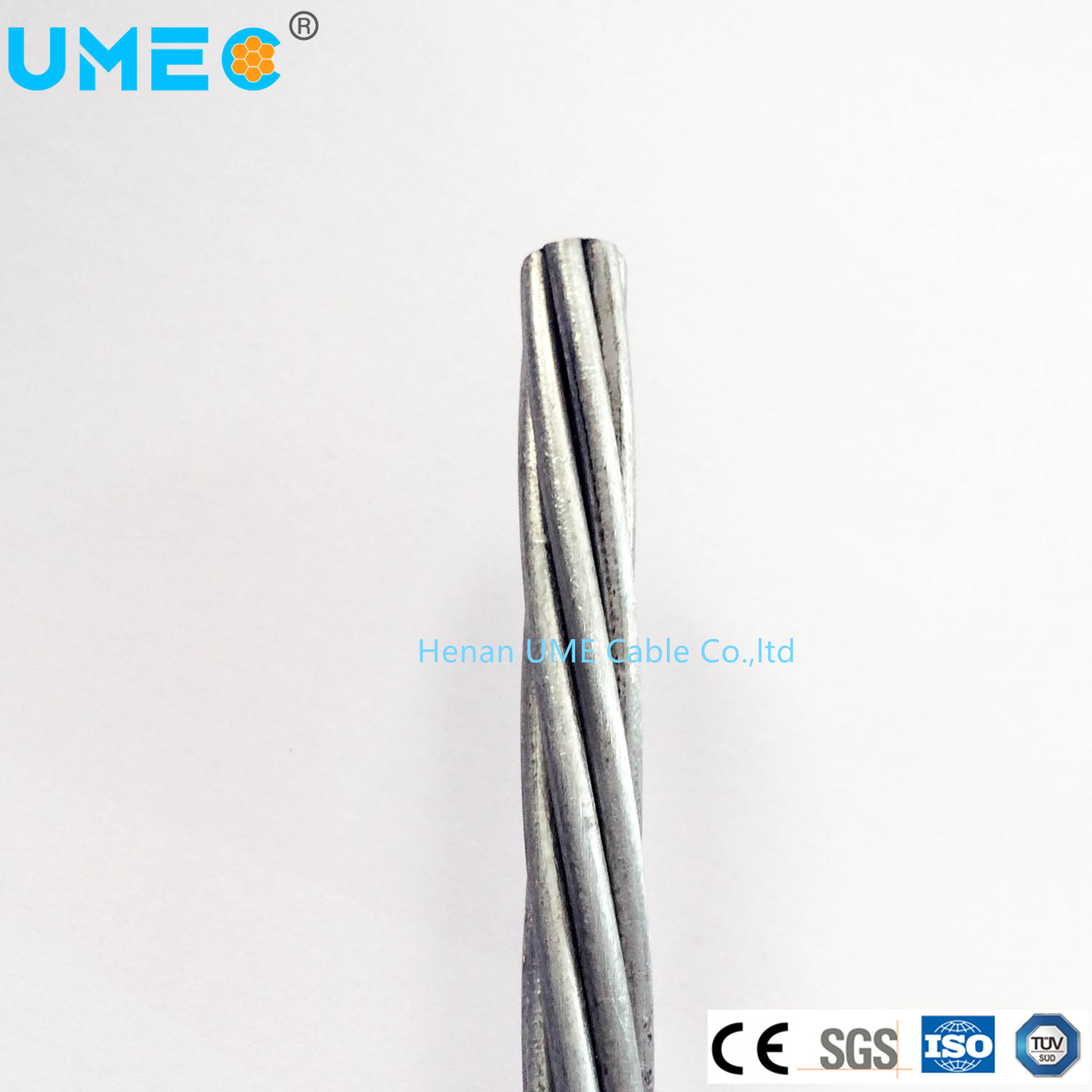

BS183 Standard General High Tensile Strength 7/3.68mm 7/5.26mm Galvanized Steel Reinforced Wire Electrical Cable

BS183 Standard General High Tensile Strength 7/3.68mm 7/5.26mm Galvanized Steel Reinforced Wire Electrical Cable image

Get Latest Price Request a quote

You May Like

Product Details

Product Description

ONE-STOP SOLUTIONS FOR WIRES&CABLES – HENAN UME CABLE CO., LTD

Over 30 years of Wires and Cables manufacture experience and Export to over 50 countries.

1. Applications

The galvanized steel wire strand is used for overhead ground lines or electrical power transmission lines. Stay or guy wire strands are produced for use with poles, towers, or any other form of guying. GSW is also used for the cord of the ACSR conductor.

2. Standard

Concentrically stranded Galvanized steel wire strands are available in class “A”, “B” and “C” galvanizing, “A” being the least heavy and “C” being the heaviest. Manufactured without welds per ASTM A-363 or with welds per ASTM A-475. Strands are formed to remain substantially in place when severed.

ASTM A475, ASTM A363, BS183:1972

| Galvanized Steel Wire Stand ASTM-A475 | ||||||

| Number of Wires/Dia. | Approx.Strand Dia. | Siemem Martin Grade | High Strength Grade | Extra-high Strength Grade | Approx.Weight | |

| Inch | mm | KN | KN | KN | kg/km | |

| 3/2.64 | 7/32 | 5.56 | 10.409 | 15.569 | 21.796 | 131 |

| 3/3.05 | 1/4 | 6.35 | 13.523 | 21.04 | 29.981 | 174 |

| 3/3.05 | 1/4 | 6.35 | – | – | – | 174 |

| 3/3.30 | 9/32 | 7.14 | 15.035 | 23.398 | 33.362 | 204 |

| 3/3.68 | 5/16 | 7.94 | 18.193 | 28.246 | 40.479 | 256 |

| 3/4.19 | 3/8 | 9.52 | 24.732 | 37.187 | 52.489 | 328 |

| 7/1.04 | 1/8 | 3.18 | 4.048 | 5.916 | 8.18 | 49 |

| 7/1.32 | 5/32 | 3.97 | 6.539 | 9.519 | 13.078 | 76 |

| 7/1.57 | 3/16 | 4.76 | 8.452 | 12.677 | 17.748 | 108 |

| 7/1.65 | 3/16 | 4.76 | – | – | – | 118 |

| 7/1.83 | 3/16 | 5.56 | 11.387 | 17.126 | 24.02 | 145 |

| 7/2.03 | 7/32 | 6.35 | 14.012 | 21.129 | 29.581 | 181 |

| 7/2.36 | 1/4 | 7.14 | 18.905 | 28.469 | 39.812 | 243 |

| 7/2.64 | 9/32 | 7.94 | 23.798 | 35.586 | 49.82 | 305 |

| 7/2.77 | 5/16 | 7.94 | – | – | – | 335 |

| 7/3.05 | 3/8 | 9.52 | 30.915 | 48.04 | 68.503 | 407 |

| Galvanized Steel Wire Strand BS 183 : 1972 | |||||||||

| Number of wires/Dia. | Approx.Strand Dia. | Minimum Breaking Load of Strand | Approx. Weight | ||||||

| Grade 350 | Grade 480 | Grade 700 | Grade 850 | Grade 1000 | Grade 1150 | Grade 1300 | |||

| mm | kN | kN | kN | kN | kN | kN | kN | kg/km | |

| 3/1.80 | 3.9 | 2.65 | 3.66 | – | – | – | – | – | 60 |

| 3/2.65 | 5.7 | 5.80 | 7.95 | – | – | – | – | – | 130 |

| 3/3.25 | 7 | 8.70 | 11.95 | – | – | – | – | – | 195 |

| 3/4.00 | 8.6 | 13.20 | 18.10 | – | – | – | – | – | 295 |

| 4/1.80 | 4.4 | 3.55 | 4.90 | – | – | – | – | – | 80 |

| 4/2.65 | 6.4 | 7.70 | 10.60 | – | – | – | – | – | 172 |

| 4/3.25 | 7.9 | 11.60 | 15.90 | – | – | – | – | – | 260 |

| 4/4.00 | 9.7 | 17.60 | 24.10 | 35.20 | – | – | – | – | 390 |

| 5/1.50 | 4.1 | 3.10 | 4.24 | 6.18 | – | – | – | – | 69 |

| 5/1.80 | 4.9 | 4.45 | 6.10 | 8.90 | – | – | – | – | 95 |

| 5/2.65 | 7.2 | 9.65 | 13.25 | 19.30 | – | – | – | – | 220 |

| 5/3.25 | 8.8 | 14.50 | 19.90 | 29.00 | – | – | – | – | 320 |

| 5/4.00 | 10.8 | 22.00 | 30.15 | 43.95 | – | – | – | – | 490 |

| 7/0.56 | 1.7 | 0.60 | 0.83 | 1.20 | – | 1.70 | 1.98 | 2.24 | 14 |

| 7/0.71 | 2.1 | 0.97 | 1.33 | 1.94 | – | 2.75 | 3.19 | 3.60 | 28 |

| 7/0.85 | 2.6 | 1.39 | 1.90 | 2.80 | – | 3.95 | 4.57 | 5.15 | 31 |

| 7/0.90 | 2.7 | 1.55 | 2.14 | 3..1 | – | 4.45 | 5.12 | 5.80 | 35 |

| 7/1.00 | 3 | 1.92 | 2.64 | 3.85 | – | 5.50 | 6.32 | 7.15 | 43 |

| 7/1.25 | 3.8 | 3.01 | 4.10 | 6.00 | – | 8.55 | 9.88 | 11.15 | 67 |

| 7/1.40 | 4.2 | 3.75 | 5.17 | 7.54 | 9.16 | 10.75 | 12.35 | 14.00 | 84 |

| 7/1.60 | 4.8 | 4.90 | 6.75 | 9.85 | 11.95 | 14.10 | 16.20 | 18.30 | 110 |

| 7/1.80 | 5.4 | 6.23 | 8.55 | 12.45 | – | 17.80 | 20.50 | 23.20 | 140 |

| 7/2.00 | 6.0 | 7.70 | 10.55 | 15.40 | – | 22.00 | 25.30 | 28.60 | 170 |

| 7/2.36 | 7.1 | 10.70 | 14.70 | 21.40 | – | 30.60 | 35.20 | 39.80 | 240 |

| 7/2.65 | 8.0 | 13.50 | 18.50 | 27.00 | – | 38.60 | 44.40 | 50.20 | 300 |

| 7/3.00 | 9.0 | 17.30 | 23.75 | 34.65 | – | 49.50 | 56.90 | 64.30 | 392 |

| 7/3.15 | 9.5 | 19.10 | 26.20 | 38.20 | – | 54.55 | 62.75 | 70.90 | 430 |

| 7/3.25 | 9.8 | 20.30 | 27.85 | 40.65 | – | 58.05 | 66.80 | 75.50 | 460 |

| 7/3.65 | 11.0 | 25.60 | 35.15 | 51.25 | – | 73.25 | 84.20 | 95.20 | 570 |

| 7/4.00 | 12.0 | 30.90 | 42.20 | 61.60 | – | 88.00 | 101.00 | 114.00 | 690 |

| 7/4.25 | 12.8 | 34.75 | 47.65 | 69.50 | – | 99.30 | 114.00 | 129.00 | 780 |

| 7/4.75 | 14.0 | 43.40 | 59.45 | 86.80 | – | 124.00 | 142.70 | 161.30 | 970 |

| 19/1.00 | 5.0 | 5.22 | 7.16 | 10.45 | – | 14.92 | 17.16 | 19.40 | 120 |

| 19/1.25 | 6.3 | 8.16 | 11.19 | 16.32 | – | 23.32 | 26.81 | 30.31 | 180 |

| 19/1.40 | 7.0 | 10.24 | 14.04 | 20.47 | – | 29.25 | 33.64 | 38.02 | 230 |

| 19/1.60 | 8.0 | 13.37 | 18.35 | 26.75 | – | 38.20 | 43.93 | 49.66 | 300 |

| 19/2.00 | 10.0 | 20.90 | 28.65 | 41.78 | 50.74 | 59.69 | 68.64 | 77.60 | 470 |

| 19/2.50 | 12.5 | 32.65 | 44.80 | 65.29 | 79.28 | 93.27 | 107.30 | 121.30 | 730 |

| 19/3.00 | 15.0 | 47.00 | 64.50 | 94.00 | 114.10 | 134.30 | 154.50 | 174.60 | 1050 |

| 19/3.55 | 17.8 | 65.80 | 90.27 | 131.60 | 159.90 | 188.00 | 216.30 | 244.50 | 1470 |

| 19/4.00 | 20.0 | 83.55 | 114.60 | 167.10 | 203.00 | 238.70 | 274.60 | 310.40 | 1870 |

| 19/4.75 | 23.8 | 117.85 | 161.40 | 235.70 | 286.00 | 336.70 | 387.20 | 437.70 | 2630 |

Technical Data

| Intensity level |

Wire diameter |

Min. tensile strength |

Min. stress with 1% extension |

Min. Extension percentage when L=250 |

Min. No. of 3600 twist |

| mm | Mpa | Mpa | % | ||

| General | 1.24~2.25 | 1340 | 1170 | 3.0 | 16 |

| 2.25~2.75 | 1310 | 1140 | 3.0 | 16 | |

| 2.75~3.00 | 1310 | 1140 | 3.5 | 16 | |

| 3.00~3.50 | 1290 | 1100 | 3.5 | 14 | |

| 3.50~4.25 | 1290 | 1100 | 4.0 | 12 | |

| 4.25~4.75 | 1290 | 1100 | 4.0 | 12 | |

| 4.75~5.50 | 1290 | 1100 | 4.0 | 12 | |

| High | 1.24~2.25 | 1450 | 1310 | 2.5 | 16 |

| 2.25~2.75 | 1410 | 1280 | 2.5 | 16 | |

| 2.75~3.00 | 1410 | 1280 | 3.0 | 16 | |

| 3.00~3.50 | 1410 | 1240 | 3.0 | 14 | |

| 3.50~4.25 | 1380 | 1170 | 3.0 | 12 | |

| 4.25~4.75 | 1380 | 1170 | 3.0 | 12 | |

| 4.75~5.50 | 1380 | 1170 | 3.0 | 12 | |

| Very high | 1.24~2.25 | 1620 | 1450 | 2.0 | 14 |

| 2.25~2.75 | 1590 | 1410 | 2.0 | 14 | |

| 2.75~3.00 | 1590 | 1410 | 2.5 | 12 | |

| 3.00~3.50 | 1550 | 1380 | 2.5 | 12 | |

| 3.50~4.25 | 1520 | 1340 | 2.5 | 10 | |

| 4.25~4.75 | 1520 | 1340 | 2.5 | 10 | |

| 4.75~5.50 | 1520 | 1270 | 2.5 | 10 |

3. Production process

HENAN UME CABLE CO., LTD has a strict quality control policy in every step from the order to After-sales service!

Production:

- Raw material inspection and test

- Production process test

- Unqualified product control

- Regular test and examination

- Finished product inspection

UME CABLE was founded in 1994, located in Zhengzhou Gongyi Huiguo Town, and occupies a total area of more than 200,000 square meters, with a building area of 20,000 square meters. The real capital assets are more than USD 6 million, with a total of 230 staff members, 35 of which are professional and technical experts. The land of our factory and employees numbers might not be the top scale of industry, but our highly automatic facilities and elite employees are the best in the industry will guarantee you a high yield rate achieved by strict cost and quality control, this is why we could quote better quality with a most competitive price within the market.

Q1: Are you a manufacturer?

Yes, we are the manufacturer.

Q2: What are your main products?

Our products range as follows:

1. Electrical wire/PVC Building Wires.

2. PVC/XLPE insulated Power Cables up to 110kv.

3. Overhead Aerial Bundle Cable/ABC Cables.

4. Bare Conductors, like AAC, AAAC, ACSR, ACAR, ASCR/AW, and so on.

5. Steel wire/strand-like EHS, GSW and ACS(Aluminum Clad Steel), CCS(Copper Clad Steel).

6. Rubber Cables, Mining Cables, Welding Cable, and Control Cables.

7. Concentric Cables with Copper/Aluminum/Aluminum Alloy 8000s’ Conductor.

Q3: Do you provide samples? Is it free or extra?

Yes, we could offer the samples for free

Q4: Is the quality of your products guaranteed?

We have passed ISO9001, ISO14001, ISO45001, and all our products have CE certificates.

Q5: Which markets do you involve mainly in?

Our products have been exported mainly to Africa, the Middle East, Southeast Asia, South America, Central America, North America, Europe, Australia, etc.

Q6: What is your payment term?

T/T or L/C

Q7: What about the delivery time?

Generally, it is 3-7days if the goods are in stock. Or it is 7-30days if the goods are not in stock, it is according to quantity.

We are China BS183 Standard General High Tensile Strength 7/3.68mm 7/5.26mm Galvanized Steel Reinforced Wire Electrical Cable manufacture and supplier,You can get more details with Email,you will get cheap price or factory price.

Get Latest Price Request a quote

Tags: Electrical Steel Wire, HENAN UME CABLE CO., Ltd., Spring Wire