Copper Winding Wire Class C 220 C

Copper Winding Wire Class C 220 C image

Get Latest Price Request a quote

You May Like

Product Details

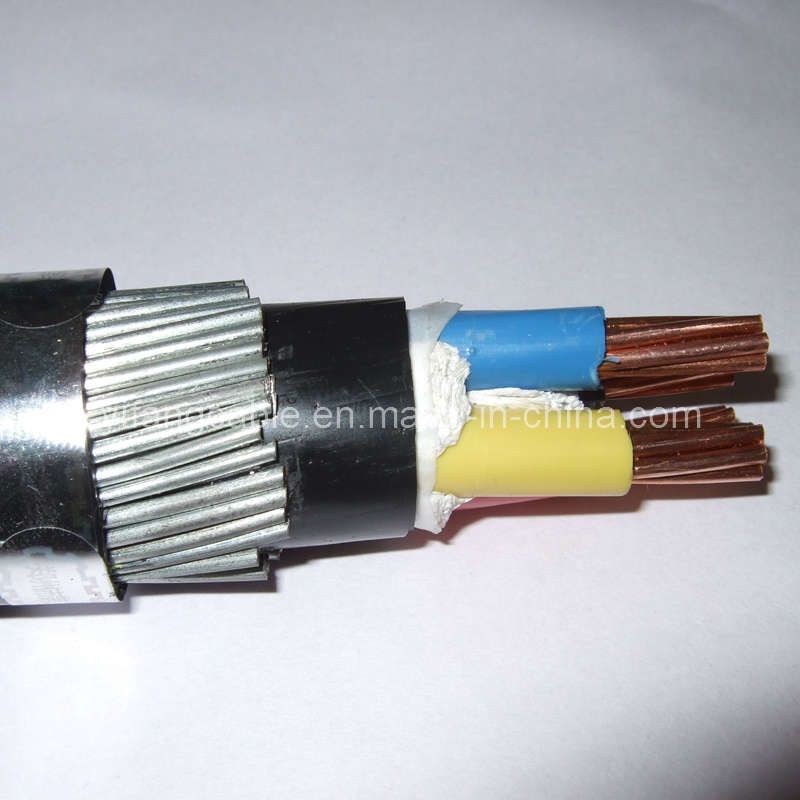

Conductor Material

Copper

Material Shape

Round Wire

Range of Application

Overhead

Certification

ISO9001, CE, CCC, RoHS, VDE

Alternative Application

Overhead

Transport Package

Wooden Drum

Production Capacity

300km/Month

Product Description

The insulation covering has good heat-resistant mechanical properties and solvent-resistant.

Improved mechanic, chemical and thermal performance in comparison to Polyester enameled copper wires

Used in various motors

With nearly 25 years of development and dedication, we are pride in the following achievements:

Production carapacity:

Annual output: 100, 000 metric tons

Product size range: 0.05mm-3.20mm(SWG9-SWG47)

Product types: Class 130-class 200

Executive standards: IEC, JIS, DIN and NEMA

Management Systems:

ISO 9001: 2008

ISO TS 16949

ISO 14001: 2004

Specifaication

| Name |

Enameled Copper Wire |

| Type |

Q(ZY/XY)-1/200 |

| Diameter |

0.27mm |

| Standard |

IEC60317 |

| Test Item |

Unit |

Technical Requirement |

Test Result |

| Appearance |

|

bright and clean, Uniform color, |

Ok |

| Overall Diameter |

mm |

< =0.302mm |

0.295 |

| Conductor Diameter |

mm |

0.270± 0.004 mm |

0.27 |

| Roundness Tolerance |

mm |

< =0.004 mm |

0.002 |

| Thickness of insulation film |

mm |

> =0.018mm |

0.025 |

| Elongation |

|

> =22 % |

30% |

| spring-back angle |

|

< =47 |

43 |

| Flexibility and adhesion |

winding test |

1D |

1 |

| Jerk test |

No Crack, and No losing adhesion |

OK |

| heat shock |

|

0.630mm |

ok |

| cut-through resistance |

|

320C, 2Min no breakdown |

2 |

| Resistance to solvent |

|

1H |

1 |

| Breakdown Voltage |

KV |

> =2.2 KV |

7.6 7.0 6.8 6.2 7.7 |

| scratch resisting(Average) |

N |

3.25 N |

7.98 |

| scratch resisting(Min) |

N |

2.75 N |

7.12 |

| package |

|

Meet the export standards |

Ok |

| Enamel Film continuity |

|

< =25 /30m |

0 |

| Quality Control Result |

|

Ok |

Send your message to this supplier

Cathodic Protection Cable

More

Find Similar Products By Category

Supplier Homepage

Products

Bare Conductor

Copper Winding Wire Class C 220 C

Related Categories

Power Cable

Communication Cable

Audio & Video Cable

Retractable Extension Cord

Wire Covering For Wall

6mm Armoured Cable

We are China Copper Winding Wire Class C 220 C manufacture and supplier,You can get more details with Email,you will get cheap price or factory price.

Get Latest Price Request a quote

Popular Bare Conductor Products

795MCM ACSR DRAKE Aluminium Conductor Steel Reinforced ASTM B 232 For Overhead Transmission Line

Customized 37*3.59mm Bare Conductor AAAC Flint ASTM B399 Aluminum Alloy Bare Conductor Price

Wholesale High Voltage High Strength Stranding ACSR Cable 100mm2 125 mm2 160mm2 ACSR Cable (Aluminum Conductor Steel Reinforced)

Aluminum Core AAC Conductor None Insulated Exported to Europe

Aluminum AAC AAAC ACSR Guy Wire Overhead Bare Conductor

ASTM B524 Aluminium Conductor Reinforced Acar AAC AAAC Conductor for Overhead Power Transmission Line

Popular Winding Wire Products

No related articlesPopular YIFANG ELECTRIC GROUP INC. Products

Two Core Cable 60AMPS 10sqmm Solidal with Two Copper Communication Cable

Astmb232 ACSR Rail 954mcm Aluminum Wire 45/3.7mm, Steel Wire 7/2.47mm

0.6/1kv Four Core Aluminum Conductor PVC Insulation 2.5 mm 3 Core Armoured Cable 10 Sq mm 2 Core 3 Core Aluminium Armoured Cable Price

BS Standard BS215 or IEC 61089 300 mm2 ACSR Ferret Bare Conductor Overhead Line Conductor ACSR (Aluminum Conduct Steel Reinforced)

China Supplier LV Aerial Bundled Conductor Overhead Line XLPE Insulation Cable ABC 3X50+54.6mm2 NFC33-209

25mm 4mm 6mm 10mm House Wiring Electrical Cable Price

Popular Products

DIN 48201 Aluminum-Clad Steel Conductor Acs

National Electrical Bare Conductor All Aluminum Alloy 6201 Conductor AAAC 300mcm 350mcm 400mcm

ACSR BS215 50mm2 Rabbit 6/1/3.35mm

ASTM 48201 Aluminum Clad Steel Conductors Acs

AAC ACSR AAAC Acar Conductor

Overhead Galvanized Steel Wire XLPE Insulated Aluminum Alloy AAC AAAC Conductor ACSR

Tags: Bare Conductor, Winding Wire, YIFANG ELECTRIC GROUP INC.

FAST AND RELIABLE SERVICE FOR YOUR PROJECT

Contact our trained experts today to find your perfect power solution.

ASK A QUESTION